QP1-B01

Plastic Glad Hand Trailer Lockouts

- Brand: BOZZYS

- Model: QP1-B01

- Product Name:Plastic Glad Hand Trailer Lockouts

- Dimensions: Outer diameter 66mm x Outer diameter 74mm x Outer diameter 80.9mm

- Installation Dimensions: Outer diameter 74mm * Inner diameter 53.7 * Inner diameter 29.6mm

- Material: PA+ABS engineering plastic

- Colors: Red, Black; Customizable

Colour:

Product Specifications

- Plastic Glad Hand Trailer Lockouts

- Keep the trailer in its place – especially while itis being loaded or unloaded.

- Apply the Plastic Glad Hand Trailer device to lockout access to the trailer’s emergency brake (red) connection – preventing it from being moved. In order to move the trailer, the Plastic Glad Hand Trailer Lockouts must be taken off the trailer’s air line to connect to a truck, which releases the emergency brakes on the trailer. Also, ideal for use on idle or storage trailers – preventing the trailer and its contents from being moved away . Available in visible red plastic with built in Brass Key Lock Cylinder.

Detailed Features

- Carefully Selected Materials: The heavy-duty truck handgrip valve air source lock is made of PA+ABS engineering plastic, wear-resistant and impact-resistant, suitable for harsh environments such as outdoors and docks.

- Universal Design: Compatible with most handgrip valve air source interfaces on the market, while also accommodating European and American standards, eliminating the need for separate adaptations for different vehicle models/container types.

- Lightweight and Compact Design: Easy to carry and install, suitable for narrow interface spaces.

- Through a precise sealing design with rubber parts aligned with the air holes, the air source interface is effectively sealed and isolated after locking, preventing air source leakage during downtime and ensuring the safety of energy isolation.

- Dustproof design effectively resists dust intrusion at docks/during transportation, extending the service life of truck handshake valves.

- Integrated lock cylinder design with a unique, non-copyable key, ensuring locking security.

- High-visibility red warning for easy identification during on-site security inspections

Applicable Scenarios

Suitable for logistics companies, dock storage enterprises, container operators, etc.

Usage Instructions

- Use the provided key to open the lock, disassembling it into two parts: A (with lock cylinder) and B (U-shaped component). (Note: To ensure a tight seal, please clean the air supply interface before locking to remove impurities and oil.)

- Insert A (with lock cylinder) into the valve port from one side, ensuring the rubber parts are precisely aligned with the air vent for a secure seal.

- Insert B (U-shaped component) from the other side, bringing A and B together as close as possible. Rotate the key 90 degrees counterclockwise and remove it. Move the sliding cover to complete the locking operation.

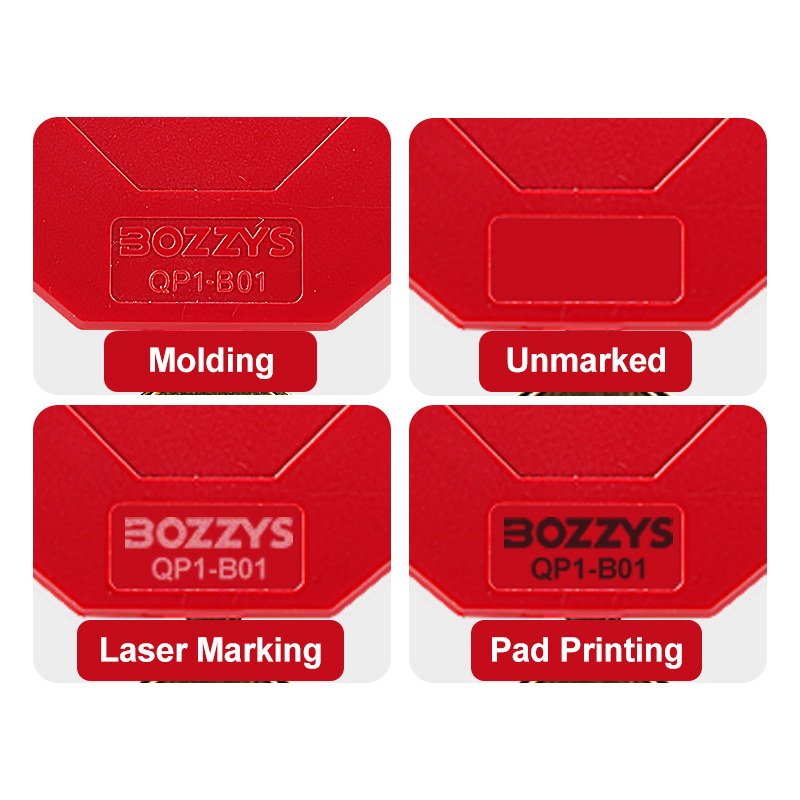

Customization Services

Brand Guarantee

- 15 Years of Industry Experience: Deeply rooted in the LOTO field, serving 5000+ industrial enterprise clients

- Customization Service: Supports customization of special specification keyhole locking devices; 3-minute response time, 3-day solution development, and 30-day fast delivery.

- After-Sales Commitment: 3-year product warranty, free technical consultation and installation guidance.

- Compliance Support: Assists enterprises in OSHA/GB standard compliance training and solution optimization.

How to buy the right product?

BOZZYS for you Custom exclusive lock listing program!

BOZZYS for you Custom exclusive lock listing program!

Related products recommendation